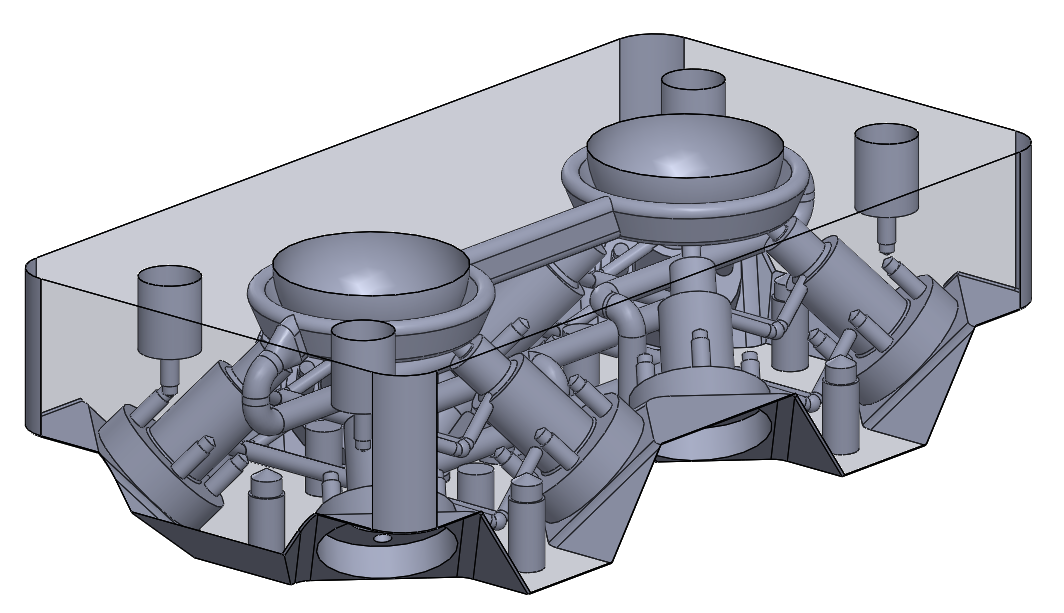

Support in the process of designing and manufacturing plastic injection moulds

- Making of the concepts, dfm analyses, moldflow simulations,

- Thermography, analysis and proposals for optimisation of the current state of the tool,

- Construction of electrodes and edm plans,

- Preparation for wire erosion, turning and milling,

- Manufacturing of complete 2d technical documentation,

- Manufacturing of accurate bom with suppliers list,

- Colouring of 3d models according to the tolerances and surface quality demands as an alternative to the 2d documentation,

- Manufacturing of maintenance manuals, technical mould requirements, etc.

At the customer’s request we join his team and lead a complete tool-manufacturing project with the end customer. With our experiences, we advise companies at raising their research and development to a higher technological level.